3D Printing in Automotive Prototyping and Production

3D printing technology is revolutionizing the automotive industry by offering numerous benefits. One of the key advantages is the ability to customize parts according to specific needs and requirements. This customization flexibility allows manufacturers to create complex geometries and lightweight structures that are not easily achievable through traditional manufacturing methods. As a result, 3D printing enables the production of highly optimized and efficient components, leading to enhanced performance and fuel efficiency in vehicles.

Another significant benefit of 3D printing in the automotive industry is the reduction in lead times for production. Traditional manufacturing processes often involve lengthy lead times due to tooling and setup requirements. In contrast, 3D printing allows for rapid prototyping and on-demand production, significantly speeding up the overall manufacturing process. This accelerated production timeline not only improves time-to-market for new vehicle models but also enables manufacturers to quickly respond to changes in design or production requirements.

3D printing technology allows for customization of parts according to specific needs and requirements

Complex geometries and lightweight structures can be easily achieved through 3D printing

Highly optimized and efficient components lead to enhanced performance and fuel efficiency in vehicles

Reduction in lead times for production is another significant benefit of 3D printing in the automotive industry

Rapid prototyping and on-demand production speeds up the overall manufacturing process

Accelerated production timeline improves time-to-market for new vehicle models

Application of 3D Printing in Vehicle Design

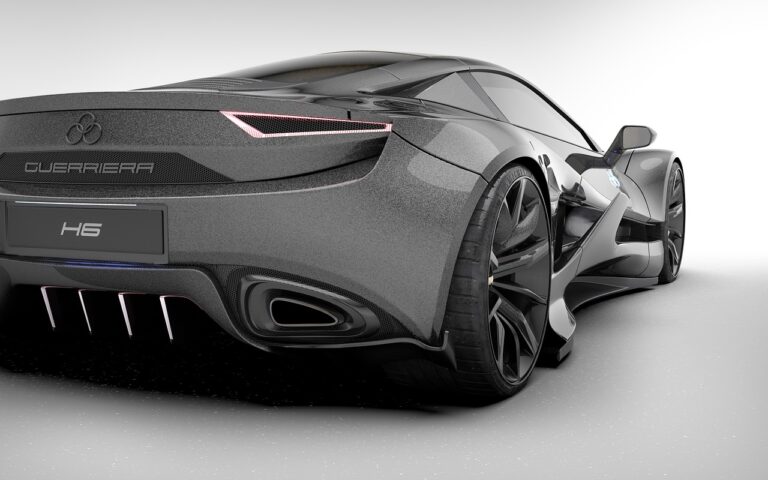

3D printing has revolutionized vehicle design processes by providing automotive engineers with a new level of flexibility and creativity. With the ability to quickly produce prototypes and parts with intricate designs, 3D printing allows for faster iteration and refinement of concepts. This not only speeds up the design cycle but also enables designers to explore innovative shapes and features that were previously difficult to achieve using traditional manufacturing methods.

Furthermore, 3D printing in vehicle design has proven to be cost-effective, especially in the prototyping phase. By eliminating the need for expensive tooling and equipment typically required for traditional manufacturing processes, automotive companies can reduce their overall production costs. This cost savings can be significant, as it allows for more experimental and customized designs without the risk of incurring high expenses.

Challenges of Implementing 3D Printing in Automotive Manufacturing

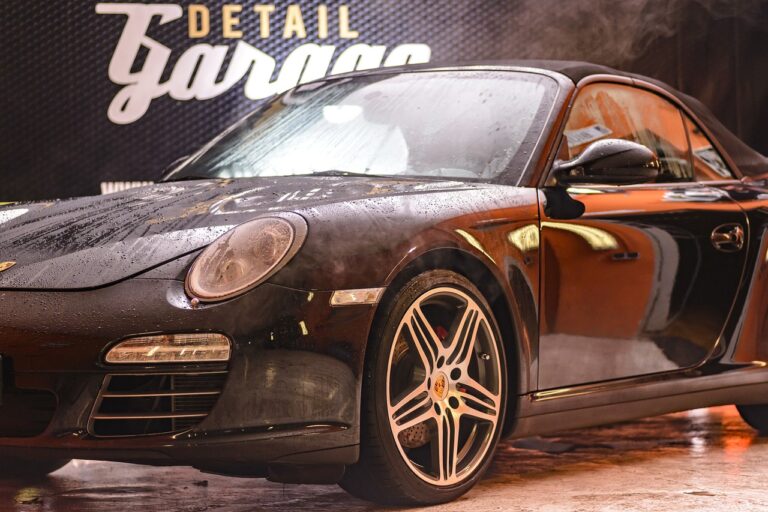

One major challenge faced in the implementation of 3D printing within the automotive manufacturing sector is the high cost associated with the technology. While 3D printing offers numerous benefits such as reduced lead times and customization options, the initial investment required for equipment and materials can be substantial. This financial barrier can deter some companies from fully embracing 3D printing in their manufacturing processes, especially smaller businesses with limited capital.

Another hurdle in the adoption of 3D printing in automotive manufacturing is the limitations in material options. While there have been advances in developing various materials suitable for 3D printing, the range and quality of materials still lag behind traditional manufacturing methods. This can restrict the potential applications of 3D printing in producing certain automotive components that require specific material properties, such as high durability or heat resistance. Overcoming these material limitations is crucial for the widespread integration of 3D printing in the automotive industry.

What are the benefits of 3D printing in the automotive industry?

3D printing in the automotive industry provides faster prototyping, reduced costs, customization options, and the ability to create complex shapes and designs.

How is 3D printing used in vehicle design?

3D printing is used in vehicle design to create prototypes, tooling, and even some final parts. It allows for faster iterations and testing of designs.

What are some challenges of implementing 3D printing in automotive manufacturing?

Some challenges include high costs of equipment and materials, limitations in material strength and quality, and the need for specialized expertise in operating and maintaining 3D printers.