Understanding the 5 Ton Rice Mill Project Cost: A Complete Guide for 2025

Starting a rice milling business can be a profitable venture, especially in regions where rice is a staple food. With the growing demand for processed rice, investing in a modern rice mill with a capacity of 5 tons per hour is a promising opportunity. However, one of the most common questions from potential investors is: What is the 5 Ton Rice Mill Project Cost?

This guide provides an in-depth look at the cost structure, equipment, installation, and other crucial factors involved in setting up a 5 ton rice mill. Whether you’re a first-time investor or looking to upgrade an existing facility, this blog will help you understand the financial and operational aspects of such a project.

What is a 5 Ton Rice Mill?

A 5 ton rice mill is a medium-capacity processing plant capable of producing 5 tons of finished rice per hour. This type of mill is suitable for commercial purposes and is often installed in areas with high paddy production. The plant includes equipment for cleaning, de-stoning, husking, separating, polishing, grading, and packing.

Importance of Planning Your Rice Mill Investment

Before delving into the costs, it’s essential to understand why careful planning is critical:

-

Profit Margins: Proper budgeting ensures you maximize ROI.

-

Equipment Efficiency: Choosing high-performance machinery reduces downtime and increases output.

-

Scalability: Planning allows for future expansion as market demand grows.

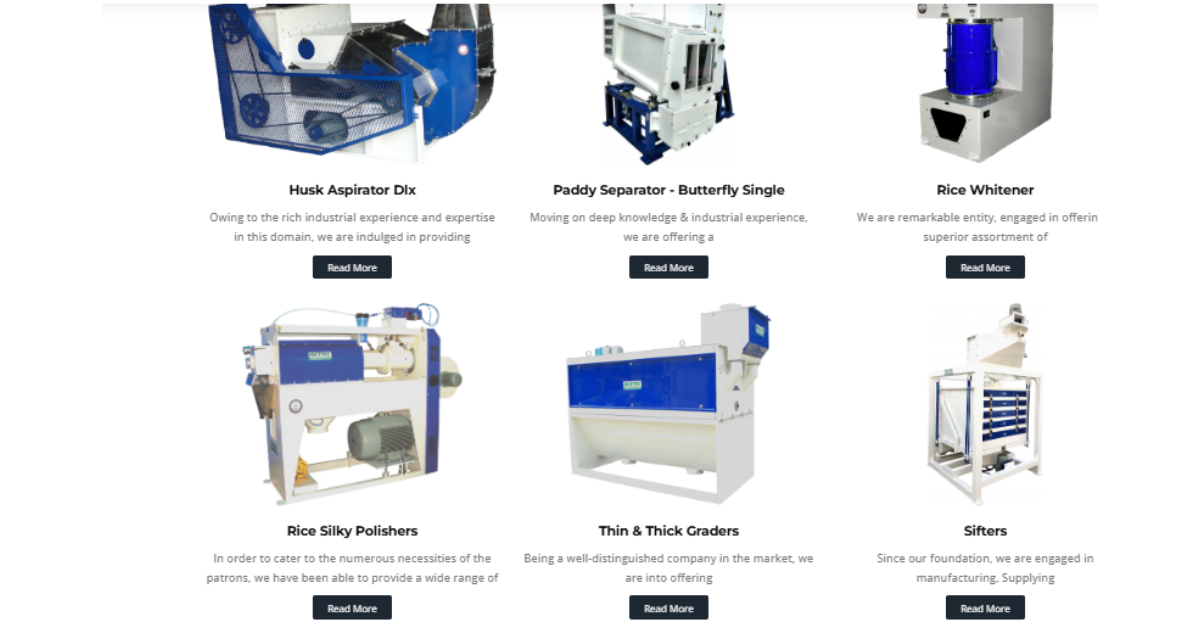

Key Components of a 5 Ton Rice Mill

To understand the 5 ton rice mill project cost, you first need to be aware of the machinery and systems involved. Here are the main components typically included:

1. Pre-Cleaning Machine

Used to remove impurities like stones, dust, and straws from raw paddy.

2. De-stoner

Separates heavy impurities like stones from the paddy.

3. Husker

Removes the husk from the paddy to produce brown rice.

4. Paddy Separator

Separates the husk from the brown rice.

5. Rice Whitener

Polishes the brown rice to produce white rice.

6. Rice Grader

Classifies rice into different grades based on size.

7. Color Sorter

Removes discolored and defective grains.

8. Packing Machine

Automatically packs the processed rice into bags for sale.

Breakdown of the 5 Ton Rice Mill Project Cost

The cost of setting up a 5 ton rice mill varies based on factors like location, machinery brand, automation level, and building infrastructure. Here’s a breakdown of typical cost components:

1. Machinery Cost

-

Standard machinery for a 5 ton per hour capacity can cost anywhere from ₹50 lakhs to ₹1.2 crores depending on the quality and brand.

-

Fully automated systems will cost more but offer long-term efficiency and labor savings.

2. Building and Civil Works

-

Constructing a facility to house the mill, storage, and offices can range between ₹20 lakhs to ₹40 lakhs.

-

Costs will vary based on location, land rates, and construction materials.

3. Installation and Commissioning

-

Installation, testing, and commissioning of equipment usually cost about ₹5 lakhs to ₹10 lakhs.

-

Professional installation ensures optimal machine performance.

4. Power Supply and Electrical Works

-

A 5 ton plant needs a stable power supply and appropriate electrical setup.

-

Expect to spend ₹5 lakhs to ₹10 lakhs on electrical panels, wiring, transformers, and backup generators.

5. Labor and Training

-

Initial labor training, hiring, and operational setup can cost around ₹3 lakhs to ₹7 lakhs.

-

Skilled operators are essential for high-efficiency output.

6. Licensing and Documentation

-

You will need industry registrations, pollution control certifications, and trade licenses.

-

Administrative and compliance costs typically add up to ₹2 lakhs to ₹5 lakhs.

7. Working Capital

-

For a smooth start, allocate ₹15 lakhs to ₹30 lakhs for raw paddy purchase, packaging, logistics, and miscellaneous expenses.

Total Estimated Cost

| Component | Estimated Cost (INR) |

|---|---|

| Machinery | ₹50,00,000 – ₹1,20,00,000 |

| Building Infrastructure | ₹20,00,000 – ₹40,00,000 |

| Installation & Commissioning | ₹5,00,000 – ₹10,00,000 |

| Electrical & Power Setup | ₹5,00,000 – ₹10,00,000 |

| Labor & Training | ₹3,00,000 – ₹7,00,000 |

| Licensing & Legal | ₹2,00,000 – ₹5,00,000 |

| Working Capital | ₹15,00,000 – ₹30,00,000 |

| Total Cost Range | ₹1.0 crore – ₹2.2 crores |

Factors Influencing the Cost

Several variables affect the 5 ton rice mill project cost, including:

1. Automation Level

Fully automated mills cost more but reduce recurring labor costs.

2. Quality of Equipment

High-end equipment from reputable manufacturers offers better durability and lower maintenance.

3. Location

Proximity to raw materials and markets can reduce logistics expenses.

4. Government Subsidies

Some state governments offer capital subsidies for agro-based industries.

Return on Investment (ROI)

The ROI for a 5 ton rice mill project depends on production efficiency and market prices. On average, such a plant can process 120 tons per day, generating significant revenue. With proper marketing and quality control, most investors recover their capital within 3 to 5 years.

Tips to Reduce Rice Mill Project Costs

-

Choose energy-efficient machinery to reduce power bills.

-

Partner with local contractors for construction to save on logistics.

-

Opt for modular designs that allow future upgrades.

-

Apply for government subsidies and low-interest SME loans.

Why Choose RiceTec Machinery for Your 5 Ton Rice Mill Project?

RiceTec Machinery is a trusted name in rice milling solutions, known for:

-

Durable and high-performance machinery.

-

End-to-end project support including design, installation, and training.

-

Customized solutions tailored to your production goals.

-

After-sales service and spare parts availability.

With decades of experience and hundreds of successful installations, RiceTec Machinery is your reliable partner in building a profitable rice milling business.Frequently Asked Questions (FAQs)

Q1. How much land is required for a 5 ton rice mill?

A 5 ton capacity rice mill typically requires about 20,000 to 30,000 sq. ft. of space to accommodate machinery, storage, and utilities.

Q2. How many workers are needed to operate a 5 ton rice mill?

Around 20 to 30 workers are generally sufficient, depending on the level of automation and shift operations.

Q3. Can I start a 5 ton rice mill with a loan?

Yes, several banks and financial institutions offer loans under MSME schemes. You may also be eligible for government subsidies or soft loans under agro-industry policies.

Q4. What are the raw materials needed for the mill?

The primary raw material is raw paddy, which can be procured from farmers or local mandis. Packaging materials and fuel for backup generators are also required.

Q5. How can I ensure the quality of the finished rice?

Using modern equipment like color sorters and polishers along with proper quality control systems ensures that your rice meets market standards.

Conclusion

The 5 Ton Rice Mill Project Cost is a significant but worthwhile investment for entrepreneurs and agribusiness owners. With careful planning, reliable machinery, and the right partners, you can establish a profitable venture that meets the growing demand for quality rice. Whether you’re starting from scratch or upgrading an existing facility, understanding the cost breakdown and return potential will guide your investment strategy.

To get a customized quote or project consultation, consider reaching out to experienced industry leaders like RiceTec Machinery.